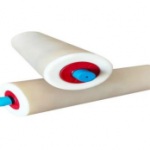

nylon idler

Scope of application: Accessories for conveyors

Diameter: 89-219mm

Load capacity: 100Kn

Length: 190-3500mm

Weight: 5-30kg

Shelf life: 1 year

Introduction: The polymer nylon roller is composed of roller skin, bearings, sealing components, and shaft. The sealing technology of this product isolates the bearing from contact with the outside world, avoiding contamination. The roller skin is made of extruded materials from the Chemical Industry Institute, and the product quality is stable. Product

product details

The polymer nylon roller is composed of roller skin, bearings, sealing components, and shaft. The sealing technology of this product isolates the bearing from contact with the outside world, avoiding contamination. The roller skin is made of extruded materials from the Chemical Industry Institute, and the product quality is stable.

Scope of use of polymer rollers

Widely used in industries such as metallurgy, mining, coal mining, chemical engineering, grain storage, building materials, ports, salt fields, and electricity, it is an excellent substitute for metal rollers.

Characteristics of polymer rollers

Compared with traditional (existing) nylon, high-density polyethylene (HDPE), laminated phenolic, ceramic, and iron rollers, it has advantages such as wear resistance, light weight, non stick materials, no damage to belts, and resistance to vibration and absorption of impact energy.

- Extremely high wear resistance, extremely low friction coefficient, and not easily worn belt;

- Superior self-lubricating properties, no need for oil injection, and less likely to get stuck when used under harsh conditions;

- Has anti-static, anti combustion, anti-aging, and chemical (acid, alkali, and organic solvent) corrosion resistance;

- Capable of withstanding repeated impacts and vibrations;

- Operating temperature range: -40 ℃ -90 ℃;

- Excellent mechanical performance, light weight, easy installation, no need for maintenance;

- Low noise (3-7DB), smooth operation, and long lifespan (3-5 times longer than the lifespan of metal rollers).

Product specifications

- Product diameter range: 89/102/108/114/127/133/140/152/159/165/178/194/219

Length range: (190mm-3500mm) for both national and non-standard rollers.

- The types of idlers include groove idlers, lower flat idlers, buffer idlers, upper and lower friction self-aligning idlers, and upper and lower conical self-aligning idlers.

- Special working conditions use: non-magnetic roller, double resistance roller.

Hebei Hengya Conveyor Equipment Co., Ltd

Hebei Hengya Conveyor Equipment Co., Ltd