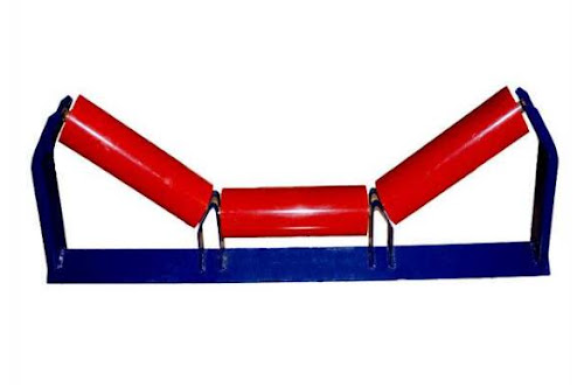

Groove shaped roller set (groove angles of 30 °, 35 °, 45 °)

Scope of application: Accessories for conveyors

Diameter: 89-219mm

Load capacity: 100Kn

Length: 500-1400mm

Weight: 5-35kg

Shelf life: 1 year

Introduction: The groove shaped (groove shaped hanging) roller set is a component used to support conveyor belts and the materials carried on them. The standard groove angle is generally divided into three types: 30, 35, and 45. This includes two types: standard type and forward leaning type. The forward leaning type can be arranged throughout the entire process to prevent the conveyor belt from deviating. The groove type roller set

product details

The groove shaped (groove shaped hanging) roller set is used to support the conveyor belt and the components carrying materials on the belt. The standard groove angle is generally divided into three types: 30 °, 35 °, and 45 °. This includes two types: standard type and forward leaning type. The forward leaning type can be arranged throughout the entire process to prevent the conveyor belt from deviating.

The correct usage method of groove roller group

- First of all, when using the troughed idler group, it is necessary to determine whether the structure, size and other aspects of the troughed idler group are sufficiently sophisticated. The component dimensions of the troughed idler group include the conveyor belt width, Flat noodles width, hopper volume, pipe diameter and container size on the conveyor. The placement and selection of the troughed idler group should fully consider the size of the above components, otherwise, the working capacity of the troughed idler group will decline, and at the same time, the conveying capacity of the conveyor will also be affected.

- Secondly, the selection of groove type roller sets should also consider factors such as material handling coefficient requirements, material unloading locations, and whether there are special requirements during the production process, so that the selected rollers can fully adapt to the requirements of the applied site. Generally, groove type roller sets have excellent characteristics such as corrosion resistance, strong wear resistance, good sealing, and long service life. However, if the selection is not comprehensive enough, it is likely that the above characteristics of groove type roller sets cannot be fully utilized.

Hebei Hengya Conveyor Equipment Co., Ltd

Hebei Hengya Conveyor Equipment Co., Ltd